Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

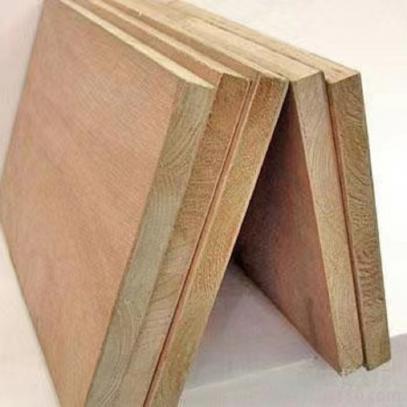

Baltic Birch Plywood for furniture and decoration

Commercial birch plywood is mainly for high level furniture. It is easy for CNC carving/die board.

*Exterior /Interior

*Stable, Resistant,

*High-Performance Plywood,

*Manufactured Using Fresh Logs

APPLICATIONS:

| EXTERIOR USE | INTERIOR USE |

| – Outdoor furnishings and fixtures

– Structures, walls, floors – Cladding, home facades, roofing – Joinery, framework, bodywork |

-Decoration

-Furniture -Door |

SPECIFICATIONS:

| Veneer Grade: | BB/BB; BB/CC ,OTHER GRADE |

| Thickness: | 2.0MM TO 40MM |

| Specification: | 1220*2440MM,1250*2500MM, other formats are available upon request. |

| Glue: | E1, E2, MR, Melamine |

| Processing of edges: | by waterproof paint in different color |

| Moisture: | ≤12% |

| Core: | Poplar, Hardwood and Combi core |

| Usage: | Furniture, Construction |

| Delivery time: | 15~25 days on receipt of deposit or original L/C |

| Mini order: | 1X20’GP |

| Price terms: | FOB, CNF |

| Payment terms: | L/C at sight, T/T 30% as deposit |

| Supply ability: | 5000 cubic meter / month |

Baltic Birch is manufactured using multi-ply consisting equally thick sheets of birch veneer that is cross-banded. Cross-Banding means the grain of these thin veneers are stacked perpendicularly and bonded together with exterior grade glue providing exceptional strength and screw holding attributes. Since Baltic Birch plywood is constructed well it holds up better that other plywood against warping or bowing especially in the thicker stocks. Baltic Birch has a beautiful clean appearance even with the exposed edge and superior strength and stability it is commonly used for making wood working tools and accessories along with furniture cabinets, drawers, children’s toys and much more.

We have 6 QC teams to inspection such as moisture control, glue inspection both before production and after production, material grade selection, pressing checking, and thickness checking. Our aim is to supply high quality product with reasonable price.

General Baltic Birch Grades:

What To Know: plywood is graded on the appearance of the face and back veneers only (not the core). The better side is called the face, the poorer side is called the back. These grades listed below read “face/back.”

B/BB: Single piece face and back veneer. Face veneers are considered clear and free of defects with a light-uniform color. Back allows 3-6 color matched patches, which are oval in shape and egg sized. Inner cores are solid birch single piece veneers.

BB/BB: Single piece face and back. Both face and back veneers allow 3-6 small color-matched patches on average and some light mineral streaks. Tight pin knots may be present. Inner cores are solid single piece veneers.

BB/CP: Single piece face and back. The “CP” back veneers are downgraded from “BB” grade veneers, which allow for unlimited patches and sound knots, but does not allow for open defects. Inner cores are solid birch single piece veneers.

CP/CP: Single piece face and back. Face and back grade veneers allow unlimited sound knots and repaired splits and unlimited patches. The panel is sound both sides and designed for laminating.

C/C: Patches, open knots, and small veneer splits allowed. Veneer lap and small core voids permitted. This panel is not sanded and would be used for structural purposes.

Judge which kind of plywood you need according to your actual situation. All kinds of plywood are produced by booster wood industry with high quality. You are welcome to order.

Other Products

CDX pine plywood for roofing and construction and outside use

Radiata PINE PLYWOOD for furniture and decoration

okoume face plywood for furniture use

Okoume or Bintangor faced block board

bintangor veneer plywood for furniture and decoration

Melamine faced OSB

Melamine paper faced plywood for cabinet making

commercial plywood for packing

RED MERANTI PLYWOOD

Product Abstract:Baltic Birch plywood has a beautiful clean appearance even with the exposed edge and superior strength and stability it is commonly used for making wood working tools and accessories along with furniture cabinets, drawers, children’s toys and much more.

Get a Free Quote