Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

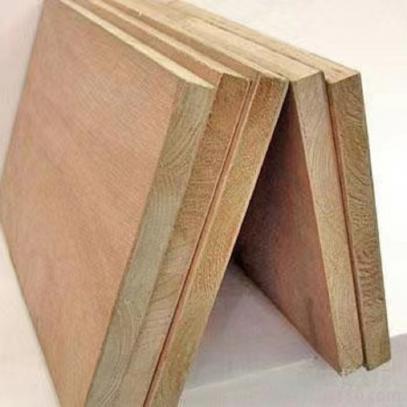

Pine is the most common type of wood used for the manufacture of plywood products of all types. Construction-grade softwood plywood is almost all made of some type of pine. This is mostly because pine is an inexpensive wood to buy, due to its commonality and high growth rate.

This long, straight trunk is ideal for the manufacture of low-cost plywood, which starts out by putting logs on a huge lathe, so that large sheets of veneer can be peeled off the log. Quarter-sawn wood veneer, used in the manufacture of hardwood plywood, doesn’t give as much yield per log. Added to the fact that hardwood trees don’t have the long straight trunk of a pine, means that much less plywood veneer can be cut from a hardwood log for the manufacture of plywood.

The resulting plywood is lightweight, in comparison to plywood made from other woods. That makes it easier to work with. Finished projects are also easy to move around. Pine itself is less expensive than other varieties of wood, such as the many types of hardwoods, therefore pine plywood is also less expensive, often considerably less expensive.

Uses

Softwood plywood is most commonly used for construction, although it is also used for industrial purposes at times. In construction, it is most often found used for wall and roof sheathing on homes, as well as for sub-flooring, although OSB is also allowable by building code for these applications, and is often used in place of softwood plywood, due to its lower costs.

This is not to say that pine plywood can only be used for construction uses. Higher grades of pine plywood are used for the manufacture of a wide variety of projects, especially by do-it-yourselfers and woodworking hobbyists. AC grade pine plywood provides the hobbyist with a plywood product that has a good surface finish, which does not have a high price. People make a considerable amount of furniture out of pine plywood, especially when they want an antique or rustic look.

Pine plywood, specifically marine grade pine plywood, is used to make boats. This is an excellent choice, because of its light weight and high strength to weight ratio. Marine grade pine plywood is manufactured without any voids, as those can cause more rapid delaminating when exposed to a high moisture environment.

Lower grades of pine plywood, such as BC grade plywood, are often used for making rough-use furniture, such as shelving and workbenches for the workshop. This provides high strength at a lower cost. Since finish isn’t so important in these applications, it makes sense to use the BC grade plywood, rather than the more expensive AB or AC grade.

We have 6 QC teams to inspection such as moisture control, glue inspection both before production and after production, material grade selection, pressing checking, and thickness checking. Our aim is to supply high quality product with reasonable price.

Pine plywood for furniture and decoration

*Exterior /Interior

*Stable, Resistant,

*High-Performance Plywood,

*Manufactured Using Fresh Logs

APPLICATIONS:

| EXTERIOR USE | INTERIOR USE |

| – Outdoor furnishings and fixtures

– Structures, walls, floors – Cladding, home facades, roofing – Joinery, framework, bodywork

|

-Decoration

-Furniture -Door |

SPECIFICATIONS:

| Veneer Grade: | BB/BB;BB/CC ,OTHER GRADE |

| Thickness: | 2.0MM TO 40MM |

| Specification: | 1220*2440MM,1250*2500MM, other formats are available upon request. |

| Glue: | E1,E2,MR, Melamine |

Judge which kind of plywood you need according to your actual situation. All kinds of plywood are produced by booster wood industry with high quality. You are welcome to order.

Other Products

Melamine paper faced plywood for cabinet making

bintangor veneer plywood for furniture and decoration

CDX pine plywood for roofing and construction and outside use

SAPELE PLYWOOD

Radiata PINE PLYWOOD for furniture and decoration

Baltic Birch plywood for furniture and decoration

PENCIL CEDAR PLYWOOD for furniture

RED MERANTI PLYWOOD

Okoume or Bintangor faced block board

Product Abstract:Pine is the most common type of wood used for the manufacture of plywood products of all types. Construction-grade softwood plywood is almost all made of some type of pine. This is mostly because pine is an inexpensive wood to buy, due to its commonality and high growth rate.

Get a Free Quote